TECHNICAL SPECIFICATIONS:

Working area

Swing diameter 500 mm 19.68 in

Turning diameter max 390 mm 15.35 in

Turning length max 1250 mm 49.21 in

Distance between centers 1250 mm 49.21 in

Chuck diameter 250 mm 9.84 in

Bar diameter max 65 mm 2.55 in

Spindle bore diameter 87 mm 3.42 in

Draw bar diameter (internal) 68 mm 2.67 in

Spindle dia. in front bearing 130 mm 5.11 in

Spindle Power (100/40%) 25/34 kW 33/45 HP

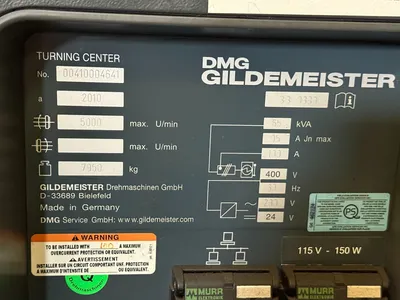

Speed range 5000 RPM

Torque, max. (100/40%) 280/380 Nm 206/280 lb*ft

Speed of C-axis 200 RPM

C-axis Torque 280 Nm 206 lb*ft

Angular value, min. 0.001°

Upper slide traverse X1 450 (-10) mm 17.71 (-0.39) in

Upper slide traverse Y1 ±100 mm ± 3.93in

Upper slide traverse Z1 1300 mm 51.18 in

Rapid traverse X/Y/Z 30 m/min 1181 IPM

Turning-milling spindle tool CAPTO C6

Speed range, max. 12000 RPM

Milling Spindle Power (100/40%) 13/22 kW 17.7/29.5 HP

Spindle torque, max. 60/100 Nm 44/74 lb*ft

Angular value, min. 0.001°

Locking moment 1000 Nm 737.6 lb*ft

B-axis Positioning angle ±110°

Speed range B1 36,000°/min

Torque B-axis, 1 344/614 Nm 254/453 lb*ft

Angular value, min 0.001°

Locking moment (pneumatic) 2800 Nm 2065 lb*ft

Tool disc magazine positions 24

Tool dia./tool length max. 80/300 mm 3.14/11.8 in

Tool weight max. 7 kg 15.4 lbs

Tailstock traverse 1200 mm 47.2 in

Tailstock Center MT 5

Power Requirements 400 VAC, 60 Hz, 3 Ph - 72 kVA

Dimensions 5.7x2.7x2.1 m 223 x 107 x 81 in

Weight 7950 kg 17526 lbs

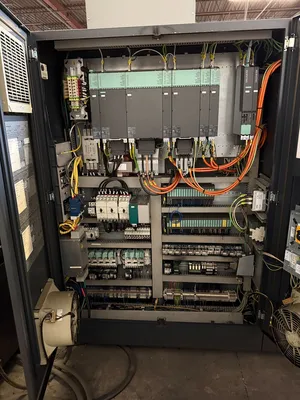

- Siemens 840 Solution Line with ERGOline CNC Control and Shop turn

- Chip Conveyor

- Coolant Tank & Pump

- Chip Blaster High Pressure Coolant (1000 PSI)

- Tool Pre-setter

- Tool Breakage monitoring

- Tailstock

- Live Tooling

- C & Y-Axis Live Tooling Capability

- 10" SMW AUTOBLOK Hydraulic Chuck

- Automatic Tool Pre-setter

- Full Set of Turning and Live Milling Holder Available CAPTO C6

- Cutting Time 5613 hrs.

We use cookies to improve your experience. Privacy Policy.